Mechanical Engineering

July 21, 2021 2024-11-12 17:12Mechanical Engineering

Mechanical engineering is no more an engineering related to only design, production and operation of machine by man. Modern mechanical engineering involves Mechatronics, Automation, Robotics, Software based Analysis and Design, Computer Aided Manufacturing using CNC machines and so on.

To train the students in these modern aspects the Mechanical Engineering department at Techno NJR has state of art labs, advance software tools, and equipment. The department has also tied up with several national and international organizations to make students industry ready. Past graduates form Mechanical Engineering are placed in Bosch, Mahindra & Mahindra, JK Tyre, TCS, Amazon, Capgemini, Jyoti CNC, Secure Meters, JBM, Pyrotech, Fractal Analytics, Grey Orange, Udaipur Cement, Sika India etc.

With Specialization in

Industry 4.0

Robotics

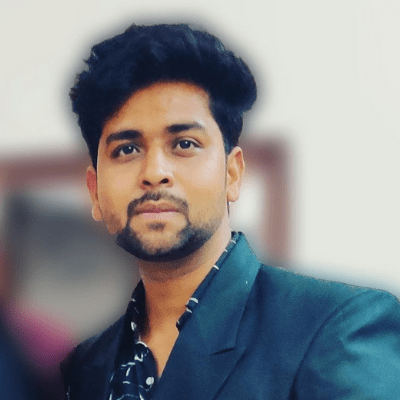

3-D Printing

Mechatronics

VISION

To increase students learning of fundamentals for Design, Develop, Analyse and Maintain the Mechanical systems and latest technologies through industry-aligned project-based learning which will help in transforming students to be good Mechanical engineering professionals leading to innovation and incubation of new ideas.

MISSION

| M1: | To create experimental learning through solving problems of Government, Society, Smart Cities, Industry and other entities. |

| M2: | To teach the latest technologies to the students as beyond the syllabus activity so that they are updated and industry ready. |

| M3: | To enable engineering students understand industry-aligned technologies and learn to find solutions from their early engineering days and this is the only way to produce globally relevant engineers solving real-life problems applying current technologies. |

| M4: | To enable students to generate projects through problems faced by and requirements of Smart cities, industry, Government, and other entities whereby those outlined problem statements are to be studied deeply by a group of faculty members to convert them into real-time project format. |

PROGRAM OUTCOMES (POs)

Engineering Graduates will be able to:

| 1 | Engineering knowledge: | Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems. |

| 2 | Problem analysis: | Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences. |

| 3 | Design/development of solutions: | Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations. |

| 4 | Conduct investigations of complex problems: | Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions. |

| 5 | Modern tool usage: | Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with and understanding of the limitations. |

| 6 | The engineer and society: | Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice. |

| 7 | Environment and sustainability: | Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development. |

| 8 | Ethics: | Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice. |

| 9 | Individual and team work: | Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings. |

| 10 | Communication: | Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions. |

| 11 | Project management and finance: | Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments. |

| 12 | Life-long learning: | Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change. |

PROGRAM SPECIFIC OUTCOMES (PSOs)

| PSO1: | To be aware of and initiate some-work on future technologies and new developments which may impact the future Industry 4.0. |

| PSO2: | Hands on training on upcoming technologies and project-based learning. |

| PSO3: | Get exposure to SAS (Smart Automation System). |

PROGRAM EDUCATIONAL OBJECTIVES (PEOs)

| PEOs 1 | To provide an in-depth understanding of the fundamentals of Mechanical Engineering and create a foundation for lifelong learning to facilitate a progressive career in the Automation Industry, as an entrepreneur and in pursuit of higher studies. |

| PEOs 2 | To equip the students with technical and analytical skills to develop innovative solutions to complex real-life problems using existing and novel technologies. To equip the students with good communication and interpersonal skills, inter-disciplinary teamwork and leadership skills to enable them to fulfil professional responsibilities. |

| PEOs 3 | To expose them to various contemporary issues which will enable them to become ethical and responsible towards themselves, co-workers, Society and the Nation. |

| PEOs 4 | To make the student’s industry ready by imparting education related to the latest technologies so that they can grab future industry jobs. |

- Robotics & Mechatronics Lab

- CAD, CAM and CAE Tool Room

- Advanced Material Testing Lab

- Automobile Lab

- Turbo-Machinery Lab

- Fluid Mechanics Lab

- Heat and Mass Transfer Lab

- KOM & DOM Lab

- IC Engine Lab

- Vibration Engineering Lab

- Design and Drafting Studio

- Mechanical Workshop

- BMW Twin Power Turbo inline 4-cylinder diesel engine

- BMW eight-speed Steptronic automatic transmission

- CNC Machine (Servo & PLC Based)

- CutViewer (CNC Simulator)

- 3D Printer

- Solidworks (Dassault Systèmes)

- ANSYS (FEA Simulation Software)

- AutoCAD (by Autodesk)

- Computerized UTM (600 kN)

- Capstan & Turret Lathe

- Turbine Test Rigs (Pelton, Kaplan and Francis) & Centrifugal Pump Test Rig

- Load Test Rig for Petrol and Diesel Engines

- Industrial Robotics and Mechatronics Training (KUKA Robot, Germany & Yaskawa Robot, Japan)

- SAE – Baja Collegiate Club

- Bosch Rexroth (Industrial Automation Technology)

- Advance CAD/CAM/CAE Training with Indo German Tool Room

- Skill Upgradation Program with MI Daksha & Pyrotech Group

- Student Chapter of Indian Institute of Industrial Engineering

- PG diploma of Indian Rubber Institute

Our Faculty

Mr. Shambhu P Choubisa

Design & Analysis

Mr. Bhupendra Kumar

Thermal Engineering

Mr. Harish Bairwa

Mr. Rajendra Singh Chouhan

Lab

Mr. Jignesh Kaneria

Mr. Rajendra Lohar

Lab

Mr. Narendra Singh Charan

Computer Based drafting modeling